Pump Repair – Polymer Repair

Pump Repair

Repairing with Polymer Material

Reading Electric, a leading supplier of Electro-Mechanical Equipment, Services, & Problem Solver for Industrial and Commercial customers for over 50 years provides technical information to the Region’s Residential, Commercial and Industrial Community. This Bulletin provides information on repairing pumps using Polymer Materials.

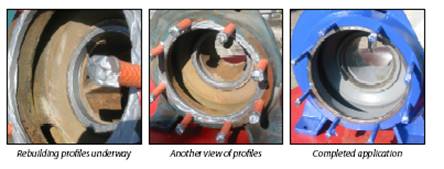

Repair Applications

A method of repairing pumps that has gained acceptance because of cost and performance utilizes multi-purpose two-component, 100% solids polymer composites. These polymer composites quickly cure to a metal-hard material and can be easily machined on a lathe, drilled, tapped, filed,

A method of repairing pumps that has gained acceptance because of cost and performance utilizes multi-purpose two-component, 100% solids polymer composites. These polymer composites quickly cure to a metal-hard material and can be easily machined on a lathe, drilled, tapped, filed,  sanded and polished. There has been sufficient actual running field experience that has confirmed this method of repair for the following equipment. Many polymers have outstanding resistance to a broad range of chemicals including inorganic acids, alkalies, hydrocarbons, mineral oils, oxidizing agents, vegetables and fats, alcohols, aqueous solutions and emulsions. Check with the polymer Manufacturer for compatibility.

sanded and polished. There has been sufficient actual running field experience that has confirmed this method of repair for the following equipment. Many polymers have outstanding resistance to a broad range of chemicals including inorganic acids, alkalies, hydrocarbons, mineral oils, oxidizing agents, vegetables and fats, alcohols, aqueous solutions and emulsions. Check with the polymer Manufacturer for compatibility.

- Worn Shafts

- Scored Rams

- Stripped Threads

- Cracked & Holed Casings

- Damaged Impellers

- Worn Key-Ways

- Holed Pipes, Tanks, Fittings, etc.

- Warped, Distorted or Steam-Cut Flange Faces

- Oversize Bearing & Bush Housings

Preparing Surface Area for Repair

The success of the repair is dependent upon the care taken in surface preparation, and is not unlike techniques used when applying most adhesive materials. In general the preparation steps are:

The success of the repair is dependent upon the care taken in surface preparation, and is not unlike techniques used when applying most adhesive materials. In general the preparation steps are:

- Remove all loose material and surface contamination

Clean with a suitable solvent which leaves no residue on the surface after evaporation such as: Acetone, MEK, Isopropyl Alcohol, etc.

Clean with a suitable solvent which leaves no residue on the surface after evaporation such as: Acetone, MEK, Isopropyl Alcohol, etc.- If necessary, apply moderate heat to remove ingrained oil and clean again with solvent.

- Roughen surface by abrasive blasting, grinding, rotary file or other appropriate means.

Note: In situations where adhesion is not desired, apply a suitable release agent (mold release compound, paste wax, etc.) to the appropriate surface.

Remember: We offer 24 / 7 Repair Service.

For more information on Pump Repairs, Contact Russ Yerger @ Reading Electric.

Recent Comments